+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

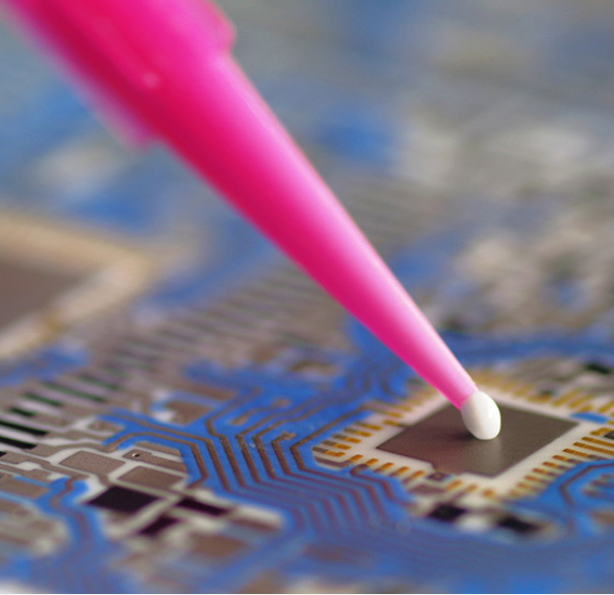

For electronic equipment heat dissipation, thermally conductive adhesive (Thermally Conductive Adhesive) is a widely used and efficient solution. It has both thermal conductivity and bonding properties, providing stable and long-lasting heat dissipation support for electronic equipment.

What is thermally conductive adhesive?

Thermal conductive adhesive is a material that has both adhesion and good thermal conductivity. It is composed of thermally conductive fillers, resins and curing agents, which can form a long-lasting and stable connection on the surface of components, playing a dual role of thermal conduction and structural support.

Main advantages of thermally conductive adhesive

1. High thermal conductivity

2. Excellent adhesion

3. Good filling and sealing properties

4. Durability and anti-aging properties

5. Easy installation and strong adaptability

Application areas of thermally conductive adhesive

LED lighting

Power module

Automotive electronics

Smart home equipment

Selection guide for thermally conductive adhesive

Thermal conductivity: Select a thermally conductive adhesive with an appropriate thermal conductivity according to the heat dissipation requirements of the device. The higher the thermal conductivity, the better the thermal conduction efficiency.

Curing method: The curing method of thermally conductive adhesive is generally divided into room temperature curing and high temperature curing.

Operation time: There will be a period of operation time after application. It is necessary to select the appropriate operation time according to the installation requirements of the equipment so as to fully adjust and apply it.

Temperature range: Select the appropriate temperature range according to the working environment of the equipment to ensure that the thermally conductive adhesive remains stable at the operating temperature of the equipment.

Adhesion: The adhesion of different products varies. Select a thermally conductive adhesive that suits the pasting requirements to achieve the best installation effect.

Precautions for using thermally conductive adhesive

Uniform application: When using, ensure that the application is uniform to avoid partial over-thickness or over-thinness, which affects the thermal conductivity effect.

Avoid bubbles: When applying thermally conductive adhesive, pay attention to avoid air from entering. Bubbles will affect the heat conduction effect and reduce the heat dissipation efficiency.

Clean surface: Before applying, ensure that the surface of the component is clean and dry, and remove dust and oil to improve adhesion and heat dissipation.