+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

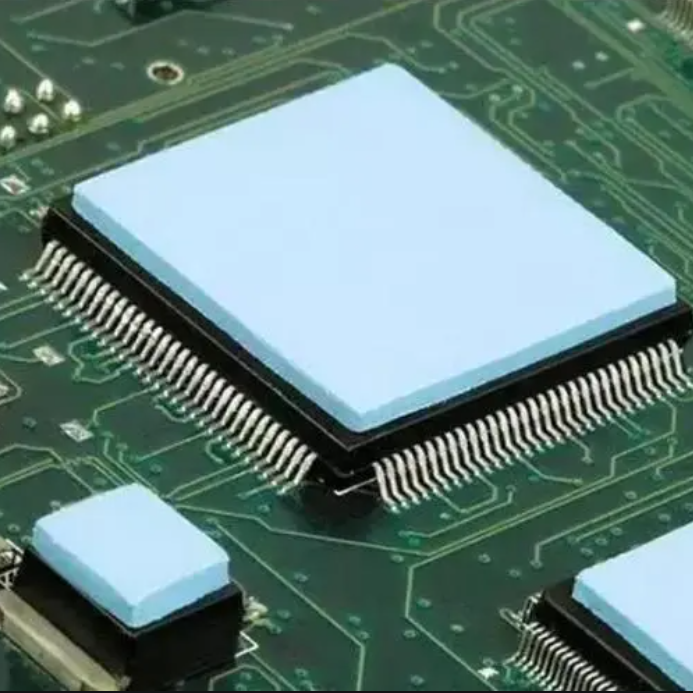

Among many thermally conductive materials, thermally conductive silicone sheet (Thermally Conductive Silicone Sheet) has become an ideal choice for electronic equipment heat dissipation due to its efficient thermal conductivity and excellent electrical insulation performance. This article will introduce the characteristics, advantages and applications of thermally conductive silicone sheet in electronic equipment in detail, and recommend this efficient heat dissipation material for you.

What is thermally conductive silicone sheet?

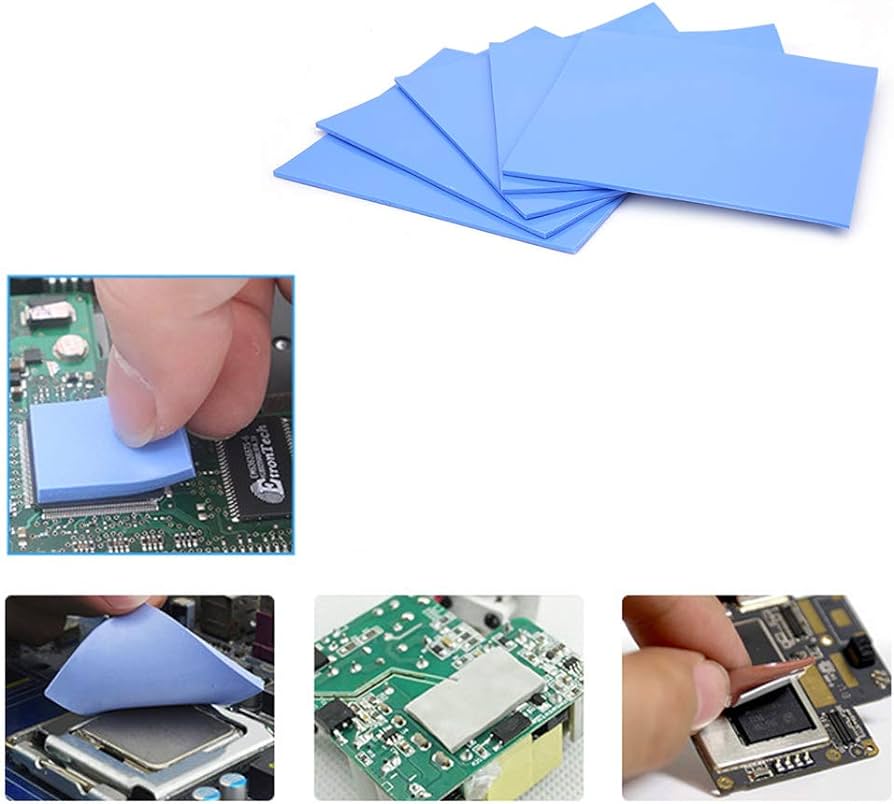

Thermally conductive silicone sheet is a soft and elastic thermally conductive material, mainly made of thermally conductive silicone, with efficient thermal conductivity and stable electrical insulation. It is in the form of a thin sheet, which is easy to cut and fit on the surface of different devices, effectively filling the gaps between devices, thereby improving heat dissipation efficiency.

Main features of thermally conductive silicone sheet

High thermal conductivity: The thermal conductivity coefficient of thermally conductive silicone sheet is usually 1-4 W/m·K, which is suitable for the heat dissipation needs of a variety of electronic devices.

Electrical insulation: In addition to excellent thermal conductivity, thermally conductive silicone sheet also has good electrical insulation.

Flexibility and adaptability: The silicone sheet material is soft and can fit tightly to irregular surfaces, fill small gaps, and effectively improve the thermal conductivity.

High temperature resistance: The temperature resistance range of thermally conductive silicone sheet is usually -40°C to +200°C, which is suitable for long-term electronic equipment.

Easy to install and customizable: thermally conductive silicone sheet can be cut into different sizes according to needs and easily fit to components such as chips, heat sinks and battery packs.

Advantages of thermally conductive silicone sheet

Efficient heat dissipation and extended equipment life

Excellent electrical insulation protection

Durability and stability

Easy installation and easy maintenance

Application scenarios of thermally conductive silicone sheet

Computers and servers

LED lighting equipment

Battery packs and electric vehicles

Communication equipment and power modules

How to choose a suitable thermally conductive silicone sheet?

Thermal conductivity: Choose the right thermal conductivity to ensure that it can meet the heat dissipation requirements of the device.

Thickness and flexibility: Too thick silicone sheet may affect the heat dissipation efficiency. Choosing the appropriate thickness can improve thermal conductivity.

Temperature range: Select the appropriate temperature range according to the operating temperature of the device to ensure that the silicone sheet can maintain stable performance under the temperature conditions of the device.

Electrical insulation: For devices that require electrical insulation, thermally conductive silicone sheets with high insulation coefficients should be preferred to prevent the risk of short circuits.

Whether it is computers, LED lamps, battery packs, or communication equipment, thermally conductive silicone sheets can help optimize heat dissipation performance and extend the service life of the device.