+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

1. Does the thermal conductivity meet the requirements?

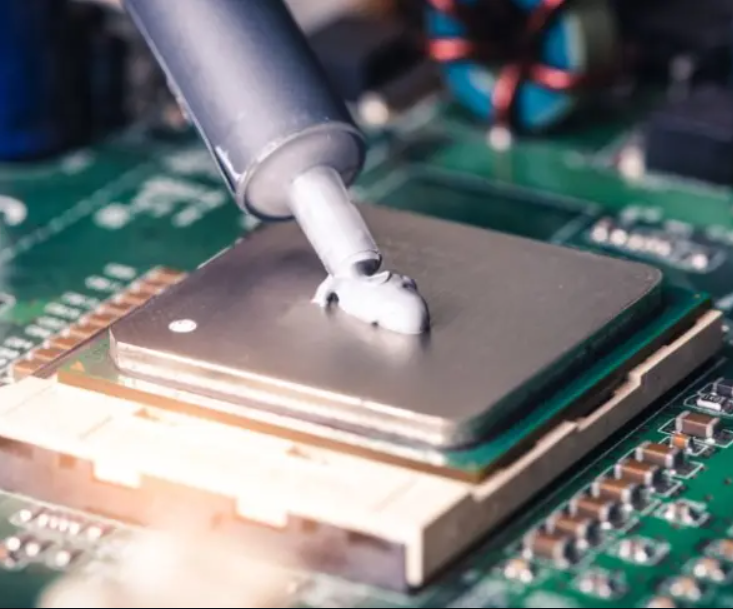

The thermal conductivity is a key indicator for evaluating the performance of thermal conductive silicone, and the unit is usually W/m·K. The higher the value, the better the heat dissipation performance. However, the higher the thermal conductivity is, the better it is. Instead, it is necessary to select the appropriate product according to the heat dissipation requirements of the specific equipment.

2. Is the electrical insulation qualified?

Many thermal conductive silicones also need to have insulation properties at the same time, especially in the heat dissipation applications of power modules and circuit boards.

3. Is the softness and fit good?

Thermal conductive silicone needs to fill the tiny gaps between the surfaces of the equipment to reduce thermal resistance and improve heat dissipation efficiency. Therefore, it is particularly important to choose thermal conductive silicone with good softness and adhesion, especially for those devices applied to irregular surfaces.

4. Is the operating temperature range suitable?

Thermal conductive silicone needs to maintain stable performance in extreme temperature environments. For example, high-temperature equipment requires materials to withstand environments exceeding 200°C, while low-temperature scenarios require that the materials do not become brittle at tens of degrees below zero.

5. Environmental and safety certifications

Make sure that the thermal conductive silicone meets environmental standards, such as RoHS or REACH certifications. Especially in markets with high environmental requirements, using certified materials can reduce the risk of later compliance.

Advantages of Jiahewell Thermal Conductive Silicone

If you are looking for high-quality thermal conductive silicone, Jiahewell's products are a trustworthy choice. Developed by the Jiangxi Research Institute team, Jiahewell Thermal Conductive Silicone has the following characteristics:

· High thermal conductivity: suitable for heat dissipation of high-performance equipment.

· Safe and environmentally friendly: passed multiple international certifications, non-toxic and harmless.

· Excellent softness: easy to fit various surfaces, good filling effect.

· Diverse choices: provide customized thermal conductive solutions to meet customer needs.