+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

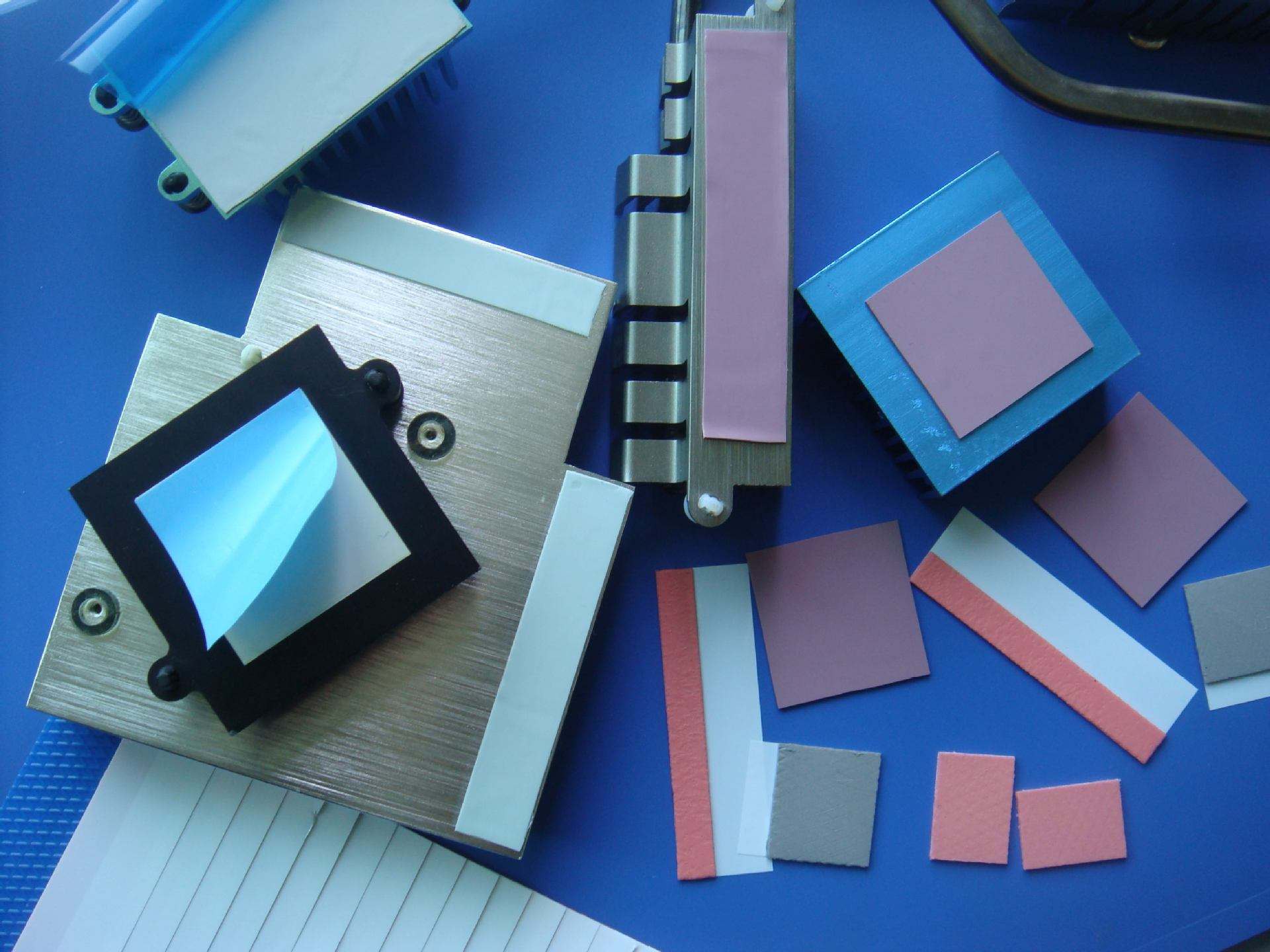

Thermal silica has excellent thermal conductivity. Its working principle is to effectively conduct heat and improve the heat dissipation efficiency of the device by filling the tiny gap between the electronic device and the radiator. When the device is running, the heat generated will be quickly conducted to the radiator through theThermal silica, thereby reducing the temperature of the device. In addition, Thermal silica can also be applied to other electronic devices, such as power supplies, circuit boards, etc., to reduce the temperature level of the entire device.

How does Thermal silica reduce device temperature?

Excellent thermal conductivity: Thermal silica has a high thermal conductivity, which can quickly conduct heat and effectively reduce the device temperature.

Filling tiny gaps: Thermal silica can fill the tiny gaps between electronic devices and radiators, increasing the heat dissipation area, accelerating heat conduction, and helping to reduce device temperature.

Improve heat dissipation efficiency: Thermal silica can effectively improve the heat dissipation efficiency of the radiator, allowing heat to dissipate from the surface of the device faster, reducing the accumulation of surface temperature of the device, and lowering the temperature of the device.

If you want to give full play to the heat dissipation effect of Thermal silica, you also need to pay attention to the following points:

Choose appropriate Thermal silica: Different electronic devices have different performance requirements for thermal silica gel. Therefore, when selecting thermal silica gel, comprehensive considerations need to be made based on the actual situation of the equipment.

Correct use of Thermal silica: Factors such as the thickness and uniformity of thermal silica gel will affect its heat dissipation effect. Therefore, when using thermally conductive silicone, you need to pay attention to the operation method to ensure that it is evenly applied and has a moderate thickness.

Comprehensive heat dissipation design: Thermal silica is only one link in the heat dissipation system. To achieve the best heat dissipation effect, other heat dissipation measures, such as fans, heat sinks, etc., need to be comprehensively considered.