+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

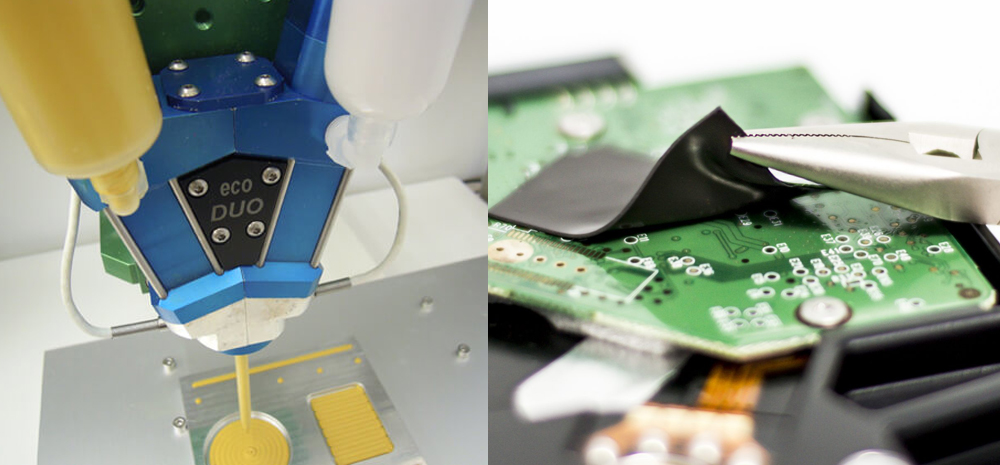

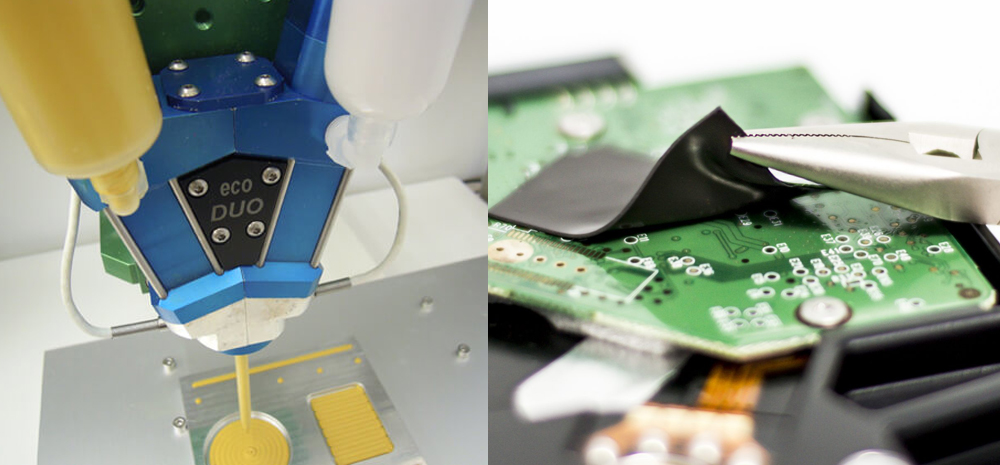

Thermally conductive gel is a soft silicone resin-based material used for filling gaps with high thermal conductivity, low interfacial thermal resistance, and good thixotropy. It is ideal for applications that require accommodating large gap tolerances.

Thermal grease is a gel-type heat dissipation product similar to liquid in form. It solidifies after heat curing, making it suitable for filling various mechanical gaps.

ProductIntroduction

Cetifications | Meet EU ROHS, REACH directive requirements |

Thermal Conductivity | ≥3.0W/m.K |

| ountry of Origin | China manufacturers |

| OEM ODM | Supply |

Thermal Grease Features

◎Excellent insulation effect.

◎Good voltage resistance, high and low temperature resistance.

◎Excellent compressibility.

◎Fireproof rating UL94 V-0.

◎Replacing traditional assembled sheets with indeterminate shapes.

◎It can be applied in different environments and can provide various thicknesses.

◎Glue can be dispensed by various manual or automated processes.

◎The desired thickness can be maintained after curing.

Technical Parameters

Test items | technical indicators | Test Methods |

color | A component: brown red B component: White | White |

Corrosive | conform to GB/T 12000-2003 | conform toGB/T 12000-2003,time 96h |

volatility | conform to GB/T 33372-2020 | GB/T 33372-2020 |

Viscosity(Cps) | A component: 25±50000 B component: 25±50000 | GB/T 2794 |

Thermal Conductivity (W/m.k) | ≥2.0 | ASTM D5470 |

Tensile Strength(Mpa) | 0.01~0.015(25℃) 0.01~0.015(55℃) | ASTM D412(bondingA1-A1) |

Shear strength(Mpa) | 0.03~0.04(25℃) 0.01~0.015(55℃) | ASTM D412(bondingA1-A1) |

Peel strength(Mpa) | 0.01~0.015(25℃) 0.01~0.015(55℃) | ASTM D412(bondingA1-A1) |

operating time(min) | ≥60@25℃ | Viscosity change≤Twice the initial viscosity |

Full curing time(h) | ≤24@25℃ | curing curve |

Density(g/cm3) | ≦1.98 | ASTM D792 |

Hardness(Shore 00) | 60±5 | ASTM D2240 |

Insulation resistance (MΩ) | ≥500 | ASTM D257 |

withstand voltage(mA) | ≤5,No breakdown, flashover phenomenon | 1800V AC,+1min |

breakdown voltage (kv/mm) | ≥8 | ASTM D149 |

Volume resistivity (Ω.cm) | ≥10¹² | ASTM D257 |

Flammability rating | V0 | UL-94 |

Silicone volatilization (ppm) | ≤150 | D3~D10 |

seawater immersion | 6~9,14~18meet the requirements | 3.5%NaC1solution immersion 4h |

Cured drawing sample size15*15*50 Glue area15*15*0.2 Cured Shear Sample Size100*25*1.5mm Glue area 25*12.5*0.2 | ||

Thermal Grease Application

◎Power battery

◎Automotive electronics

◎Communication facilities

◎Electronic equipment and peripheral applications

◎Application between heat conduction heat source and radiator

ADAS

LED Head Lamp

Battery Pack

Power Electronics

Thermally conductive gel is a soft silicone resin-based material used for filling gaps with high thermal conductivity, low interfacial thermal resistance, and good thixotropy. It is ideal for applications that require accommodating large gap tolerances.

Thermal grease is a gel-type heat dissipation product similar to liquid in form. It solidifies after heat curing, making it suitable for filling various mechanical gaps.

ProductIntroduction

Cetifications | Meet EU ROHS, REACH directive requirements |

Thermal Conductivity | ≥3.0W/m.K |

| ountry of Origin | China manufacturers |

| OEM ODM | Supply |

Thermal Grease Features

◎Excellent insulation effect.

◎Good voltage resistance, high and low temperature resistance.

◎Excellent compressibility.

◎Fireproof rating UL94 V-0.

◎Replacing traditional assembled sheets with indeterminate shapes.

◎It can be applied in different environments and can provide various thicknesses.

◎Glue can be dispensed by various manual or automated processes.

◎The desired thickness can be maintained after curing.

Technical Parameters

Test items | technical indicators | Test Methods |

color | A component: brown red B component: White | White |

Corrosive | conform to GB/T 12000-2003 | conform toGB/T 12000-2003,time 96h |

volatility | conform to GB/T 33372-2020 | GB/T 33372-2020 |

Viscosity(Cps) | A component: 25±50000 B component: 25±50000 | GB/T 2794 |

Thermal Conductivity (W/m.k) | ≥2.0 | ASTM D5470 |

Tensile Strength(Mpa) | 0.01~0.015(25℃) 0.01~0.015(55℃) | ASTM D412(bondingA1-A1) |

Shear strength(Mpa) | 0.03~0.04(25℃) 0.01~0.015(55℃) | ASTM D412(bondingA1-A1) |

Peel strength(Mpa) | 0.01~0.015(25℃) 0.01~0.015(55℃) | ASTM D412(bondingA1-A1) |

operating time(min) | ≥60@25℃ | Viscosity change≤Twice the initial viscosity |

Full curing time(h) | ≤24@25℃ | curing curve |

Density(g/cm3) | ≦1.98 | ASTM D792 |

Hardness(Shore 00) | 60±5 | ASTM D2240 |

Insulation resistance (MΩ) | ≥500 | ASTM D257 |

withstand voltage(mA) | ≤5,No breakdown, flashover phenomenon | 1800V AC,+1min |

breakdown voltage (kv/mm) | ≥8 | ASTM D149 |

Volume resistivity (Ω.cm) | ≥10¹² | ASTM D257 |

Flammability rating | V0 | UL-94 |

Silicone volatilization (ppm) | ≤150 | D3~D10 |

seawater immersion | 6~9,14~18meet the requirements | 3.5%NaC1solution immersion 4h |

Cured drawing sample size15*15*50 Glue area15*15*0.2 Cured Shear Sample Size100*25*1.5mm Glue area 25*12.5*0.2 | ||

Thermal Grease Application

◎Power battery

◎Automotive electronics

◎Communication facilities

◎Electronic equipment and peripheral applications

◎Application between heat conduction heat source and radiator

ADAS

LED Head Lamp

Battery Pack

Power Electronics