+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

In the development of modern technology, Thermal silica plays a vital role. But do you really understand its importance? This article will break down Thermal silica and reveal its key role in various applications.

What is Thermal silica?

Thermal silica is a special material, usually composed of silicone rubber and thermally conductive particles. It has excellent thermal conductivity, can effectively conduct heat, and has good flexibility and high temperature resistance.

The Importance of Thermal silica

Electronic equipment heat dissipation: In electronic equipment, such as computers, mobile phones, tablets, etc., Thermal silica is widely used in heat dissipation modules. It can effectively conduct the heat generated by the equipment to the radiator or heat sink to maintain the stable operation of the equipment.

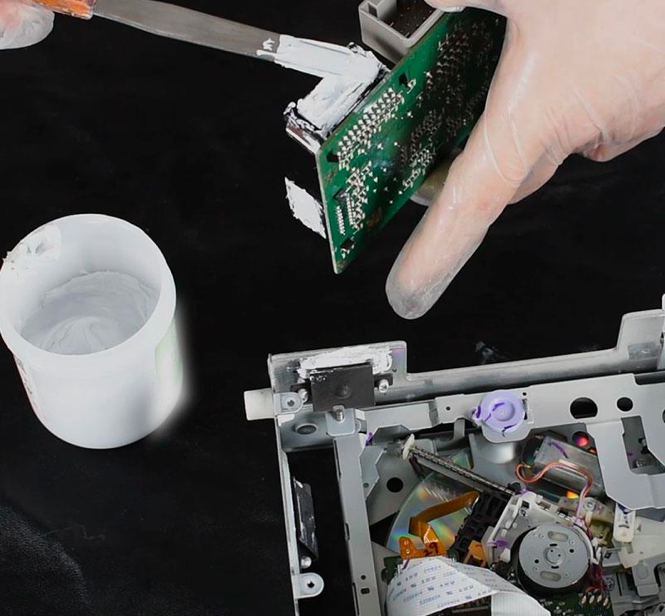

Electronic component connection: In the connection of electronic components, Thermal silica can fill the tiny gaps between components, improve heat conduction efficiency, and avoid damage to components due to high temperatures.

Automotive electronic systems: Electronic systems in modern vehicles are increasingly complex and require efficient cooling measures. Thermal silica is widely used in the heat dissipation and connection of automotive electronic components to ensure the stable operation of electronic systems.

How to choose Thermal silica?

Thermal conductivity: Choose Thermal silica with good thermal conductivity to ensure that heat can be conducted effectively.

High temperature resistance: Consider the high temperature resistance of Thermal silica, especially its long-term use in high temperature environments.

Flexibility: Choose Thermal silica with good flexibility to adapt to application scenarios of different shapes and sizes.

As an important heat dissipation material, Thermal silica plays an irreplaceable role in modern technological applications. By understanding its importance and selection points, we can better apply Thermal silica and improve the performance and stability of the equipment.

Thermal silica advantages

Extremely high thermal conductivity (5.0W/mK)

Excellent electrical insulation properties

Good flexibility and compliance

Excellent electrical insulation properties and excellent flame retardant properties

Compression relaxation properties help reduce stress on electrical components

Slight adhesive allows pre-assembly

Good wetting properties improve and reduce thermal resistance

about Us

Jiahe Cube is committed to the research and development, production and sales of new materials medical silicone. It relies on the Jiangxi Academy of Sciences to form a research and development team, breaks through technical barriers, replaces imports with domestic products, and launches a series of silicone products, which are mainly used in trauma, surgical scars, hypertrophic scars, and radiotherapy positioning. Various types of wounds, high-end dressings and medical devices, construction, automobiles, electronics, aerospace and other industries