+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

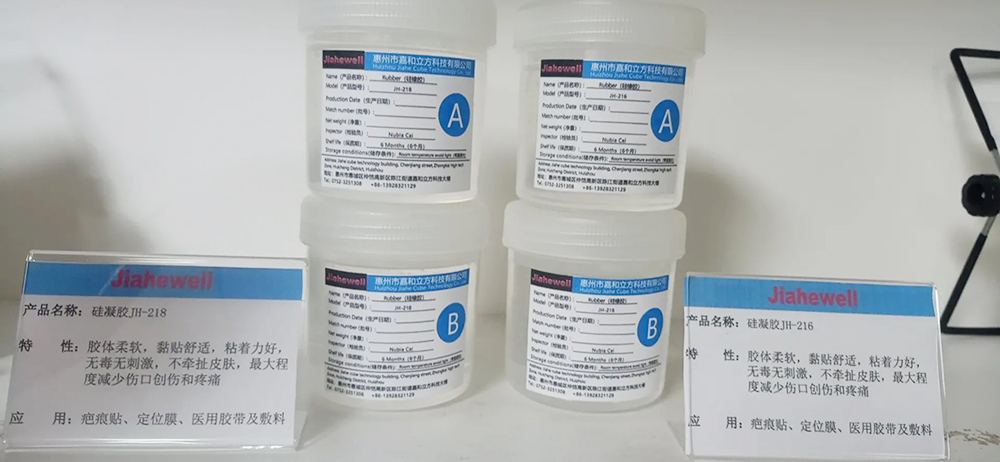

Product introduction

JH-218 medical silicone gel is a solvent-free two-component addition type silicone gel. The colloid is soft, comfortable to stick, good adhesion, non-toxic and non-irritating, does not involve the skin, minimizes wound trauma and pain, and can be passed through high-pressure steam , Ethylene oxide disinfection, stable performance, is an ideal choice for the production of various dressings

Technical Parameters

Technical Parameters

Appearance: colorless transparent liquid

A Stay Sticky: 25℃, 30000mPa·s

B Stay Sticky: 25℃, 30000mPa·s

Operating time: 25°C, ≥60min

Cured properties

Appearance: Colorless, odorless transparent gel

Initial tack: 13

Storage and shelf life

Storage conditions: dark and cool

Shelf life: 6 months

Instructions for use

1. Mix

First weigh components A and B with a mass ratio of 1:1, and then fully mix and disperse.

2. Depending on the intended use, it can be degassed

If a large amount of air bubbles are introduced during the mixing and stirring process, in order to ensure that the cured product has no air bubbles, the material should be degassed after mixing evenly. JH-218 has relatively low flow viscosity. It has certain self-exhausting foam characteristics, and whether it needs to be air-exhausted depends on the requirements.

3. Coating

The mixed silicone is applied to the carrier substrate using a doctor blade, slot die, or similar tool.

4. Curing

This product is coated on the substrate, the recommended curing condition is 85℃--100℃, 5-10min.

5. Clean

For uncured silica gel or raw materials, volatile solvents such as ethanol and ethyl acetate can be used to remove them. For the cured residual silica gel, first use external force to remove most of the silica gel, then soak it in a solvent until it swells, and then wipe it with fabric or paper

Precautions

1. Components A and B should not be mixed when not in use, and the tools used in production should not be inserted into the two material barrels at will, which will lead to deviations in product performance.

2. Viscosity can be fine-tuned by changing the ratio of components A and B. It is recommended that the adjustment ratio not exceed 5%. If necessary, please contact us in time.

3. Changes in external factors (weather, coating substrate, etc.) may affect the curing of silica gel, and a small sample test must be carried out before mass production. If there is any abnormality, please contact us in time.

4. Do not contact with compounds and materials containing amino groups, sulfur, phosphorus and tin that may poison the catalyst.

5. Avoid overheating and mixing, which will shorten the operation time

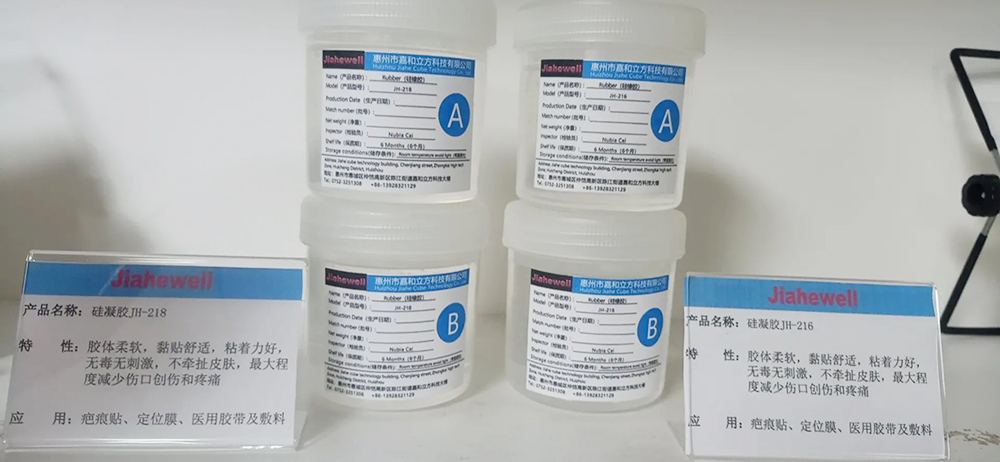

Product introduction

JH-218 medical silicone gel is a solvent-free two-component addition type silicone gel. The colloid is soft, comfortable to stick, good adhesion, non-toxic and non-irritating, does not involve the skin, minimizes wound trauma and pain, and can be passed through high-pressure steam , Ethylene oxide disinfection, stable performance, is an ideal choice for the production of various dressings

Technical Parameters

Technical Parameters

Appearance: colorless transparent liquid

A Stay Sticky: 25℃, 30000mPa·s

B Stay Sticky: 25℃, 30000mPa·s

Operating time: 25°C, ≥60min

Cured properties

Appearance: Colorless, odorless transparent gel

Initial tack: 13

Storage and shelf life

Storage conditions: dark and cool

Shelf life: 6 months

Instructions for use

1. Mix

First weigh components A and B with a mass ratio of 1:1, and then fully mix and disperse.

2. Depending on the intended use, it can be degassed

If a large amount of air bubbles are introduced during the mixing and stirring process, in order to ensure that the cured product has no air bubbles, the material should be degassed after mixing evenly. JH-218 has relatively low flow viscosity. It has certain self-exhausting foam characteristics, and whether it needs to be air-exhausted depends on the requirements.

3. Coating

The mixed silicone is applied to the carrier substrate using a doctor blade, slot die, or similar tool.

4. Curing

This product is coated on the substrate, the recommended curing condition is 85℃--100℃, 5-10min.

5. Clean

For uncured silica gel or raw materials, volatile solvents such as ethanol and ethyl acetate can be used to remove them. For the cured residual silica gel, first use external force to remove most of the silica gel, then soak it in a solvent until it swells, and then wipe it with fabric or paper

Precautions

1. Components A and B should not be mixed when not in use, and the tools used in production should not be inserted into the two material barrels at will, which will lead to deviations in product performance.

2. Viscosity can be fine-tuned by changing the ratio of components A and B. It is recommended that the adjustment ratio not exceed 5%. If necessary, please contact us in time.

3. Changes in external factors (weather, coating substrate, etc.) may affect the curing of silica gel, and a small sample test must be carried out before mass production. If there is any abnormality, please contact us in time.

4. Do not contact with compounds and materials containing amino groups, sulfur, phosphorus and tin that may poison the catalyst.

5. Avoid overheating and mixing, which will shorten the operation time