+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

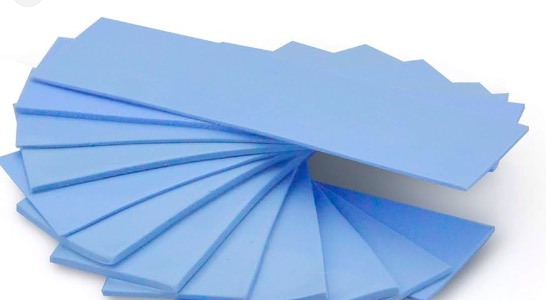

Thermal silicone usually contains thermal fillers whose purpose is to improve the thermal conductivity of the silicone. The main thermally conductive fillers include aluminum oxide, boron nitride, aluminum nitride, etc.

The thermal conduction mechanism mainly involves the heat conduction process

Selection of fillers: The fillers in thermally conductive silica gel are usually materials with good thermal conductivity, such as alumina, etc. These fillers are evenly distributed in the silica gel matrix.

Heat conduction between fillers: When there is a temperature difference between fillers, heat is conducted through the microstructure between the fillers. The filler has good thermal conductivity and can effectively transfer heat energy.

Softness of the silicone base: The base of thermally conductive silicone is usually silicone rubber or silicone materials, which are soft and elastic. Able to adapt to irregular surfaces or complex-shaped contact interfaces, thereby improving the effectiveness of thermal conduction.

The combination of filler and matrix: A good combination of filler and matrix helps to improve the overall performance of thermally conductive silicone. Make sure the filler is evenly distributed and tightly bonded to the matrix to reduce thermal resistance.

Thermal conductive silica gel is filled with thermally conductive fillers to enhance thermal conductivity. At the same time, the softness and elasticity of silica gel are used to make it suitable for various shapes and surfaces to improve the efficiency of heat conduction. It is widely used in electronic devices, radiators and other fields.