+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

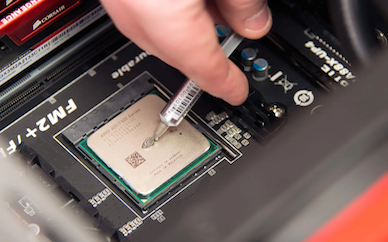

Thermal grease is a material with high thermal conductivity, usually mixed with silicone oil and thermally conductive particles. Its basic principle is to fill the tiny gaps in electronic devices and improve the heat conduction efficiency between thermally conductive materials. This improvement in thermal conductivity is critical to the stability and longevity of electronic devices.

The role of thermal conductive silicone grease

1,Interface filling: Thermal conductive silicone grease can fill the tiny gap between the chip and the heat sink, reducing the possibility of air existence, thereby improving heat transfer efficiency.

2,Improved heat dissipation: By improving the contact between thermally conductive materials, the heat absorption and transfer capabilities of the radiator are effectively improved, ensuring the stability of the equipment during high-load operation.

3,Reduce thermal resistance: Thermal conductive silicone grease forms a heat-conducting medium between electronic devices, reducing thermal resistance, making it easier to conduct heat and preventing equipment from overheating.

![]()

Thermal Grease Selection and Characteristics

1,Thermal conductivity: Thermal conductivity is a key parameter for the performance of thermal conductive silicone grease, usually in W/m·K. Choosing thermal conductive silicone grease with high thermal conductivity can improve the heat dissipation effect.

2,Stability: Thermal conductive silicone grease needs to maintain stability in high temperature environments to prevent volatilization and decomposition, which will affect the thermal conductivity effect.

3,Non-conductivity: Considering the particularity of electronic devices, a certain degree of insulation is required to prevent problems such as short circuits.