+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

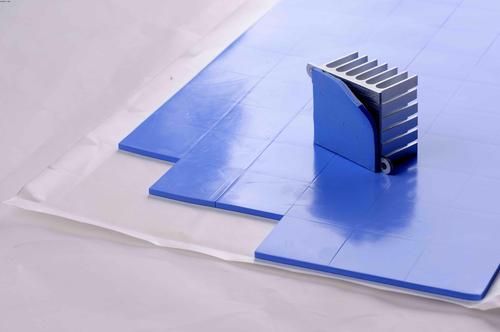

Thermal conductive silicone has excellent thermal conductivity and can conduct heat efficiently. In high-temperature environments, thermally conductive silicone can quickly transfer heat to radiators or other heat dissipation devices to prevent equipment from overheating.

1, High temperature stability: The material of thermally conductive silicone has high temperature stability and can maintain stable physical and chemical properties under extreme temperature conditions.

2, Flexibility and filling: Thermal conductive silicone has good flexibility and can fill irregular surfaces and tiny gaps. This flexibility and filling ability can maintain effective thermal contact under high temperature conditions and improve heat transfer efficiency.

![]()

3, Corrosion resistance: Thermal conductive silicone has good corrosion resistance to common chemicals and corrosive substances. In high-temperature environments, it can resist chemical corrosion and maintain its thermal conductivity and long-term stability.

4, Electrical insulation: Good electrical insulation properties effectively isolate the current between the heat source and the power supply. This is crucial for electronic devices and electronic components in high-temperature environments to ensure the safe operation of the equipment.

5, Various application fields: Thermal conductive silicone is widely used in electronics, electrical appliances, automobiles, LED lighting and other fields. In high-temperature environments, it can be used as a cooling pad, thermal pad, thermal adhesive, etc. to improve the thermal management effect of the device.

6, Easy construction and adaptability: Thermal conductive silicone has good constructability and is easy to deploy and apply. It is suitable for a variety of shapes and surfaces, providing flexible usage options to adapt to engineering needs in different high-temperature environments.