+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

The application of silicone gel as a heat dissipation material in the electronics industry can effectively improve the heat dissipation performance of equipment, mainly through the following aspects:

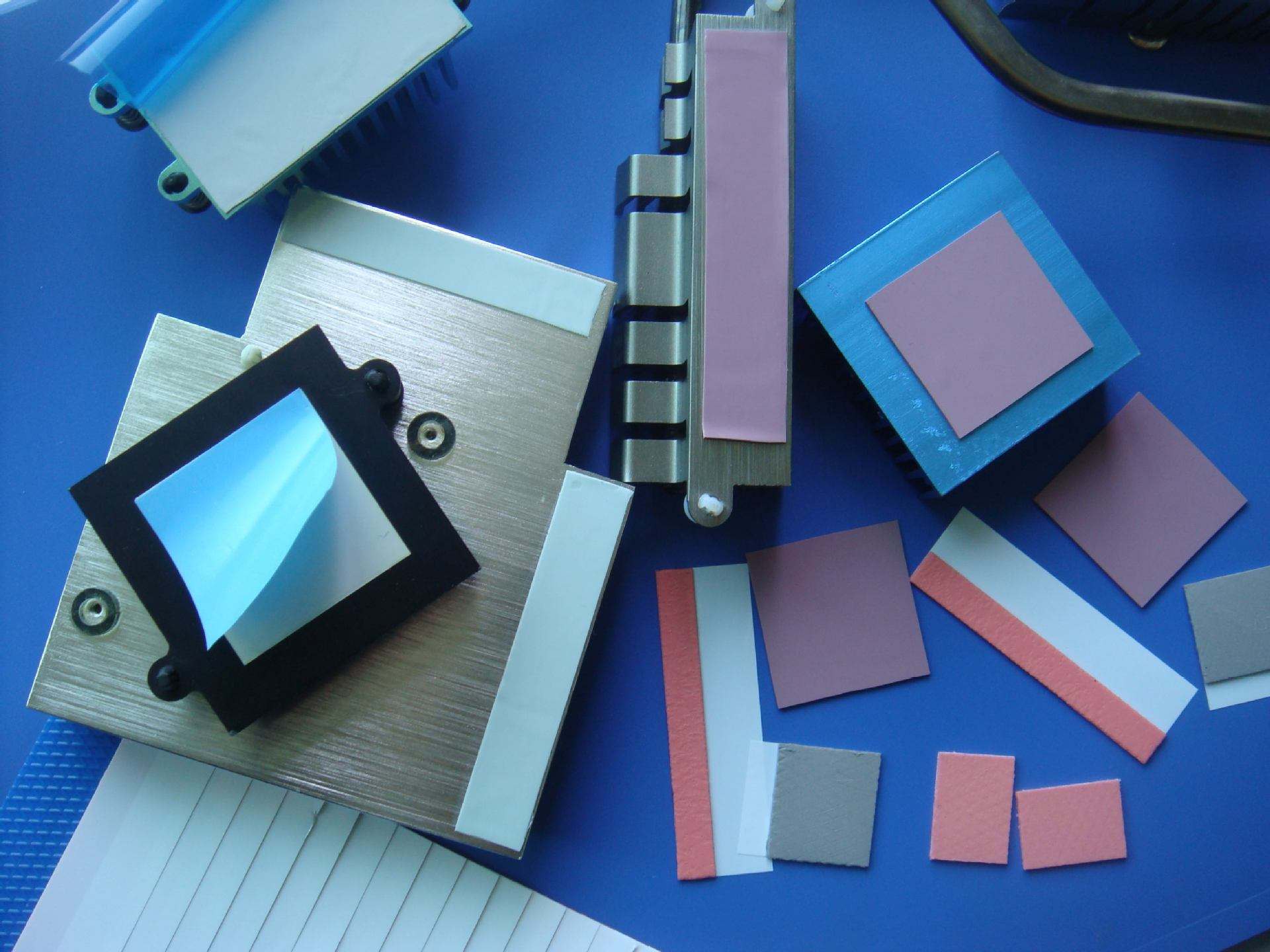

Thermal conductivity: Silicone gel has excellent thermal conductivity and excellent wettability due to its liquid properties. It can penetrate into small gaps and effectively conduct heat from the heat source to the radiator or the external environment. In electronic equipment, silicone gel is used as a thermally conductive gasket or thermally conductive adhesive to transfer heat from heating components (such as chips, processors, etc.) to the radiator or radiator fin, accelerating the transmission and dissipation of heat.

Filling the voids: Within electronic devices, there are often various voids and gaps that hinder the transfer of heat. Silicone gel can fill these gaps, effectively reducing local accumulation of heat and improving overall heat dissipation efficiency.

Increase the heat dissipation surface area: When silicone gel is used to connect the radiator to the heating element, it can fill the tiny concave and convex surfaces, increase the contact area, and improve the heat conduction efficiency. In addition, silicone gel can form a thin, uniform layer, reducing thermal resistance and further improving heat dissipation.

High temperature resistance: Electronic equipment often operates in high temperature environments, so heat dissipation materials need to have good high temperature resistance. Silicone gel has high temperature resistance and can maintain stable physical and chemical properties at higher temperatures, ensuring that heat dissipation materials can effectively function under various working conditions.

Silicone gel also has good insulating properties and can prevent current leakage and electrical short circuits, which is essential for the safe operation of electronic equipment.

about Us:

The company's research and development is based on the polymer materials research team of the Institute of Applied Chemistry, Jiangxi Academy of Sciences, with more than 20 years of independent research and development results as its core technology. It has long been involved in the fields of medical adhesives, new energy, three-electronic thermal conductivity, chip packaging, and unmanned aerial vehicles. machine. Damping oil, etc., in the cutting-edge fields, combined with industry market demand, we focus on the research and development of silicone polymers, functional medical materials, new electronic materials, etc.