+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

Silicone Gel is a material with excellent properties, and its application in the electronics and semiconductor industries is becoming more and more extensive. Due to its excellent insulation, heat resistance and flexibility, silicone plays an important role in semiconductor manufacturing and protection.

Main applications of silicone gel in semiconductors

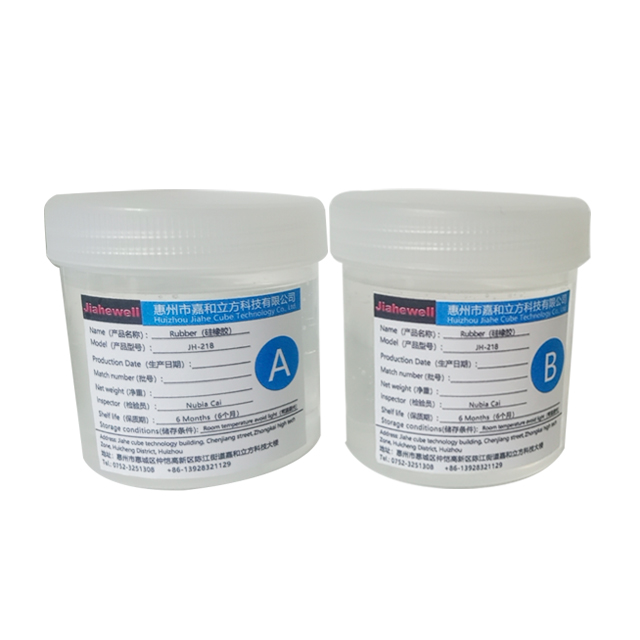

1. Packaging materials

Silicone gel is widely used in packaging materials for semiconductor chips. It has the following advantages:

·Excellent insulation: It has good electrical insulation properties, can effectively prevent current leakage, and protect semiconductor chips from external electromagnetic interference.

·High temperature resistance: During semiconductor manufacturing and application, it can withstand high temperature environments and will not lose its performance due to high temperature.

·Flexibility and durability: It has good flexibility, can adapt to the thermal expansion and contraction of the chip, and increase the durability of the package.

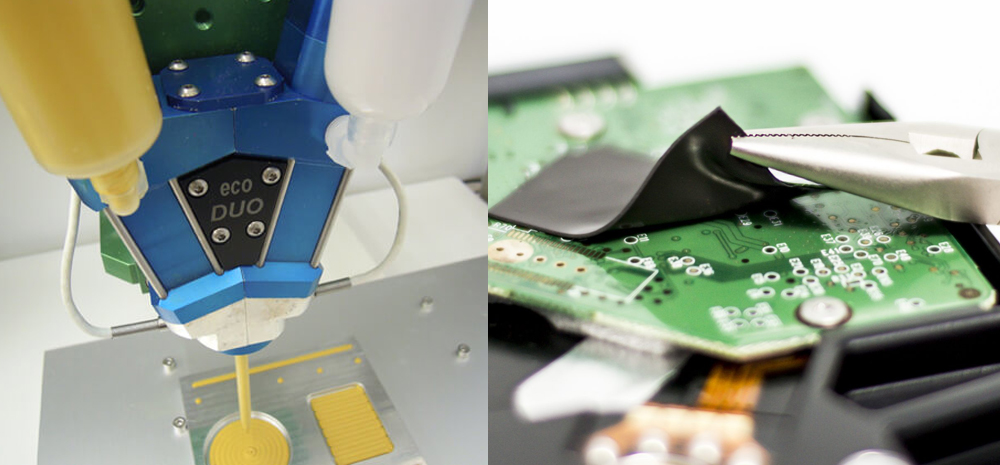

2. Heat dissipation management

Silicone gel is used as a heat dissipation material in the heat dissipation management of semiconductor devices. The main advantages include:

·High thermal conductivity: Add thermal conductive fillers to improve its thermal conductivity and help effectively dissipate heat.

· Thermal stability: Maintains stable performance in high temperature environments, helping to maintain the normal operating temperature of semiconductor devices.

3. Waterproof and sealing

Silicone gel's waterproof and sealing properties make it an ideal choice:

· Moisture-proof: Can effectively prevent moisture penetration and protect semiconductor devices from moisture.

· Chemical resistance: Has good chemical resistance and can resist corrosion from various chemicals to ensure the long life of the equipment.

4. Electrical insulation

In electronic equipment, electrical insulation is key to ensuring safety and performance.

· Insulation protection: Can be applied as an insulating coating to cables, connectors and other electronic components to prevent short circuits and electrical failures.

· Stability: Maintains stable insulation performance under various environmental conditions to ensure the safety of electronic equipment.

Summary of the advantages of silicone gel

· High insulation: Provides excellent electrical insulation protection.

· High temperature resistance: Able to maintain stable performance in high temperature environments.

· Flexibility: Adapts to thermal expansion and contraction, enhancing durability.

· Waterproof: Effectively prevents damage to electronic equipment from moisture and humidity.

· Thermal conductivity: Helps dissipate heat and maintain the stability of semiconductor devices.