+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

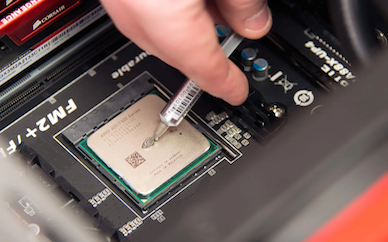

Thermal grease is a widely used thermal conductive material, which plays a vital role in the field of thermal management. The correct selection of thermal grease suitable for the project is key to ensuring efficient operation of the equipment. During the selection process, there are several key factors to consider:

Clear definition of project thermal management needs

First, you need to identify the specific thermal management needs of your project. Consider the type and size of the project, as well as the amount of heat likely to be generated, to select a thermal grease with appropriate thermal conductivity properties.

Thermal conductivity

Thermal conductivity is one of the key indicators for selecting thermal conductive silicone grease. It affects how efficiently heat is conducted within the material. Make sure the thermal grease you choose has a high enough thermal conductivity to meet the project's requirements.

Adaptable temperature range

Different thermal greases have different temperature resistance ranges. Be sure to choose one that can handle the project's operating temperature range to maintain stable thermal conductivity.

Adhesion and viscosity

The adhesion and viscosity of thermal grease are critical for stable adhesion and filling of tiny gaps inside devices. Choose a thermal grease with suitable viscosity and good adhesion to ensure optimal heat transfer.

Electrical insulation properties

For thermal grease used with electronic equipment, ensure it has excellent electrical insulation properties to avoid the risk of possible circuit short circuits.