+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

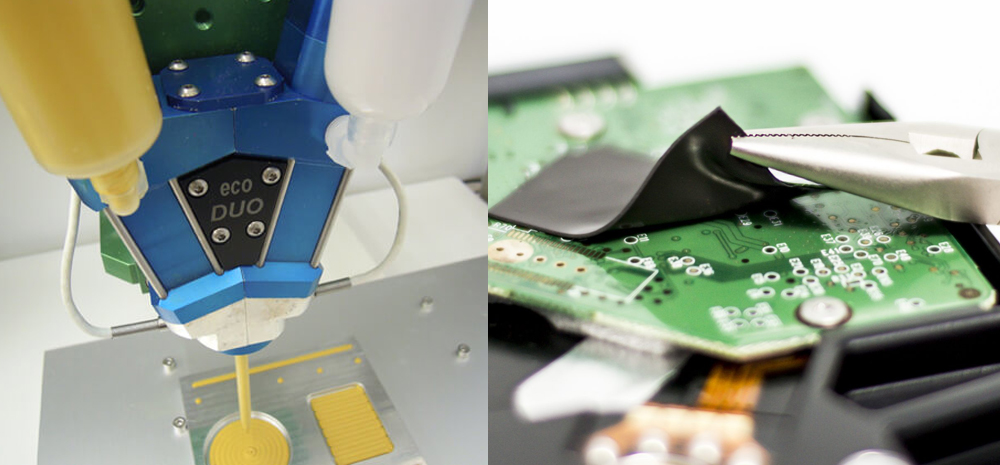

In modern electronic products, thermal grease (also known as thermal paste) plays a crucial role. As electronic devices continue to evolve, the heat generated by processors and other key components is also increasing. Effective heat dissipation solutions are essential to ensure the performance and longevity of the device.

Improve Heat Conduction Efficiency: Thermal grease fills the tiny gaps between processors, heat sinks, and other electronic components, ensuring more effective heat transfer from the heat source to the heat sink.

Reduce Thermal Resistance: By minimizing the thermal resistance at the contact interface, thermal grease effectively lowers the operating temperature of electronic devices and prevents overheating that could damage components.

Protect Electronic Components: Proper thermal management with thermal grease helps prevent overheating of electronic components, reducing performance degradation and hardware failures caused by excessive temperatures.

Modern electronic products, especially computer processors and graphics cards, process data faster, generating more heat. Thermal grease ensures that processors and graphics cards operate stably under high-load conditions by effectively conducting heat away from these components.

Thermal grease helps reduce component temperatures and minimizes aging and damage caused by high temperatures. This not only improves equipment stability but also extends its service life, reducing repair and replacement costs.

Under high-temperature conditions, the cooling system's fan may need to run at higher speeds to dissipate heat, which increases noise levels. High-quality thermal grease improves heat dissipation, reducing the workload on the fan and thus lowering noise.

Effective thermal management with thermal grease maintains stable system temperatures and enhances equipment reliability. This is particularly important for devices that need to operate continuously for extended periods, such as servers and industrial computers.

The main performance indicator of thermal grease is its thermal conductivity (W/m·K). Selecting thermal grease with high thermal conductivity ensures more effective heat transfer. Generally, thermal grease with a conductivity between 1.5 and 5.0 W/m·K is suitable for most electronic devices.

Thermal grease should remain stable in high-temperature environments. Choose thermal grease with high temperature resistance to ensure it does not fail or deteriorate under long-term high-load conditions.

Good adhesion ensures that the thermal grease does not flow or fall off during use. Opt for thermal grease with excellent adhesion to ensure it remains stable on the component’s surface and maintains long-term thermal conductivity.

Some thermal greases require special application tools or techniques, while others are designed to be easier to apply and distribute. Choosing a thermal grease that is easy to apply simplifies the installation process and reduces operational difficulty.