+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

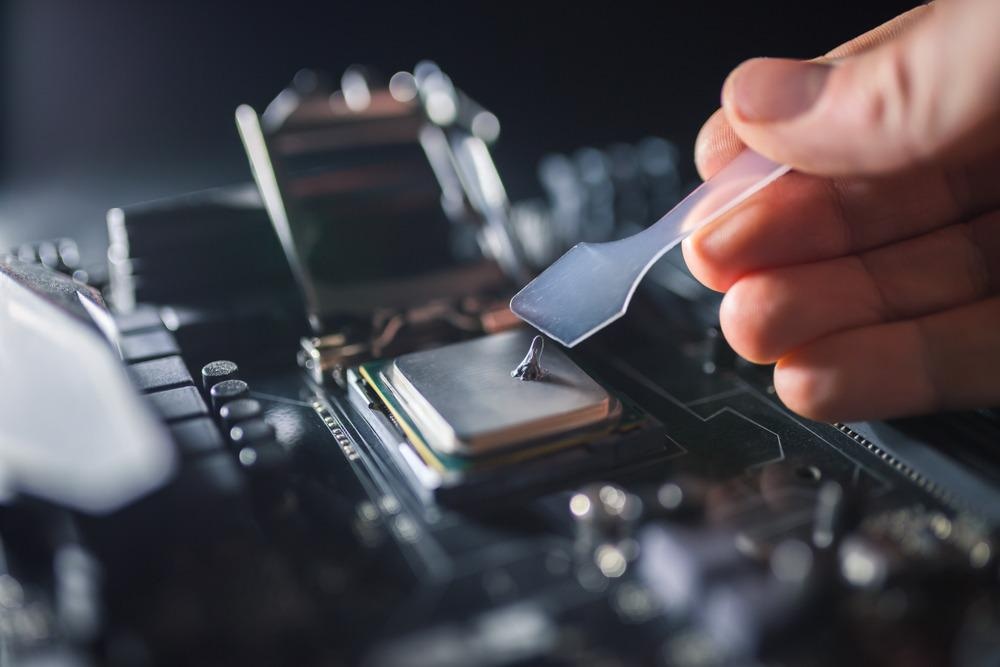

Thermal grease and traditional heat dissipation materials have different characteristics in heat dissipation applications, so it is necessary to determine which one is more suitable based on specific needs.

Thermal Grease

Advantage:

1, Dual function: Thermal conductive silicone grease not only has excellent thermal conductivity, but also has good lubrication properties, making it a unique material with the dual functions of lubrication and thermal conductivity.

2, Electrical insulation: Good electrical insulation is suitable for scenarios such as electronic components and circuit boards that need to prevent electrical failures.

3, Strong adaptability: It can work stably under different temperature and pressure conditions, has strong adaptability, and can be used in a variety of environments.

Shortcoming:

Higher cost: Compared with some traditional heat dissipation materials, the cost of thermal grease is higher, which may be a consideration in some cases where budget is limited.

Traditional heat dissipation materials

Advantage:

1, Lower cost: Traditional heat dissipation materials, such as aluminum, copper, etc., usually have lower cost and are suitable for some cost-sensitive applications.

2, Good thermal conductivity: In terms of thermal conductivity, metals such as aluminum and copper still have good thermal conductivity, and are especially suitable for the manufacture of large radiators and heat sinks.

Shortcoming:

1, No lubrication: Traditional heat dissipation materials usually do not have lubrication properties and cannot provide additional functions in the lubrication needs of mechanical equipment.

2, Heavy weight: Metals such as aluminum and copper are relatively heavy, which may limit their use in some weight-sensitive applications.