+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

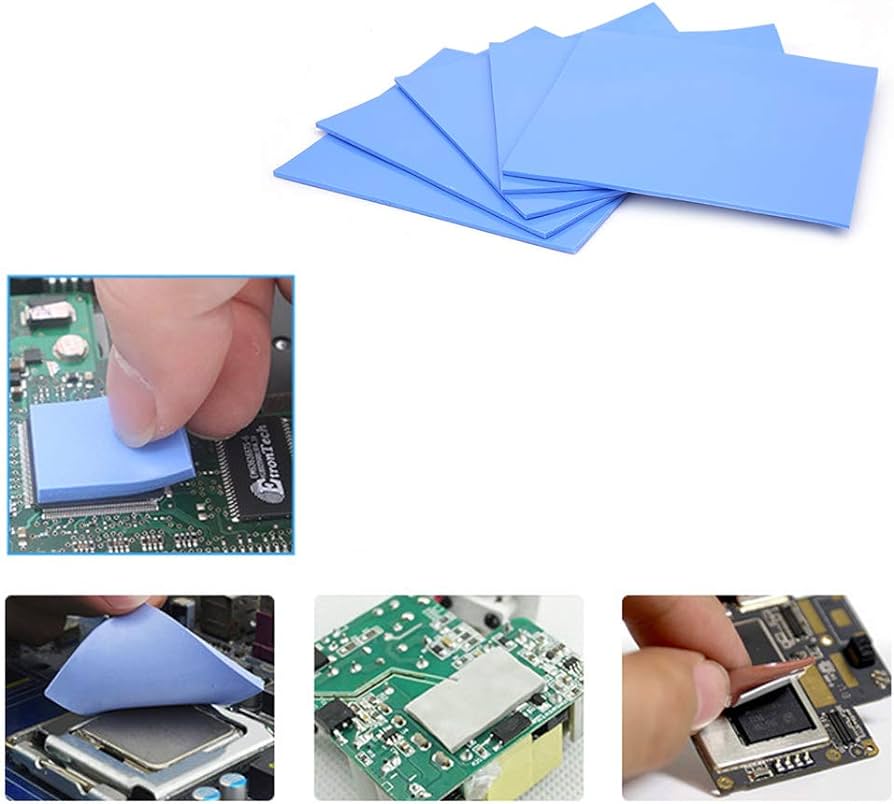

The choice of heat dissipation and thermal conductive materials is directly related to the service life of the product and user experience. Among many heat dissipation materials, thermally conductive silicone sheet has become a common heat dissipation solution for many electronic manufacturers with its excellent performance.

Thermally conductive silicone sheet: both heat dissipation and protection

Thermal conductive silicone sheet quickly transfers heat by filling gaps and using thermal conductive powder to achieve effective connection between the heat source and the heat dissipation components, ensuring that electronic products remain "cool" under high-intensity work.

Why choose thermally conductive silicone sheet instead of metal?

Here are some key factors:

Filling gaps and optimizing heat conduction: Taking the CPU and heat sink as an example, if metal is used directly, there will inevitably be a gap unless the heat sink and the CPU are tightly integrated. Once there is a gap in any heat conduction solution, its heat conduction effect will be greatly reduced.

Reduce contact thermal resistance and improve performance: Thermally conductive silicone sheet can also effectively reduce the contact thermal resistance generated between the heat source interface and the contact surface of the heat dissipation device, thereby enhancing the overall performance of electronic devices.

Thermally conductive silicone sheet: the best choice for ultra-thin electronic products

In the pursuit of lightweight and thin electronic product design trends, thermally conductive silicone sheets have become an indispensable part due to their ultra-thin, soft, and easy-to-operate characteristics.

By making full use of these excellent properties of thermally conductive silicone sheets, we can effectively avoid performance degradation or even damage of electronic products due to overheating, and provide users with a more stable and reliable product experience.