+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

Thermal grease has multiple advantages in electronic equipment heat dissipation, and the following are some of them:

Excellent thermal conductivity: Thermal grease usually has excellent thermal conductivity and can effectively conduct heat. This helps to quickly transfer the heat generated by electronic components to the radiator or cooling fan, thereby effectively reducing the operating temperature of the device and improving the heat dissipation efficiency.

Filling uneven surfaces: The surface of components in electronic devices is usually not completely flat, and there are tiny gaps or bumps. Thermal grease has a certain fluidity, which can fill these uneven surfaces to ensure that heat can be evenly conducted to the heat dissipation components and reduce thermal resistance.

Prevent oxidation and corrosion: Thermal grease usually contains preservatives, which can effectively prevent the metal surface from reducing the heat conduction efficiency due to oxidation or corrosion. This helps to protect the surface of electronic components and heat dissipation components and extend the service life of the device.

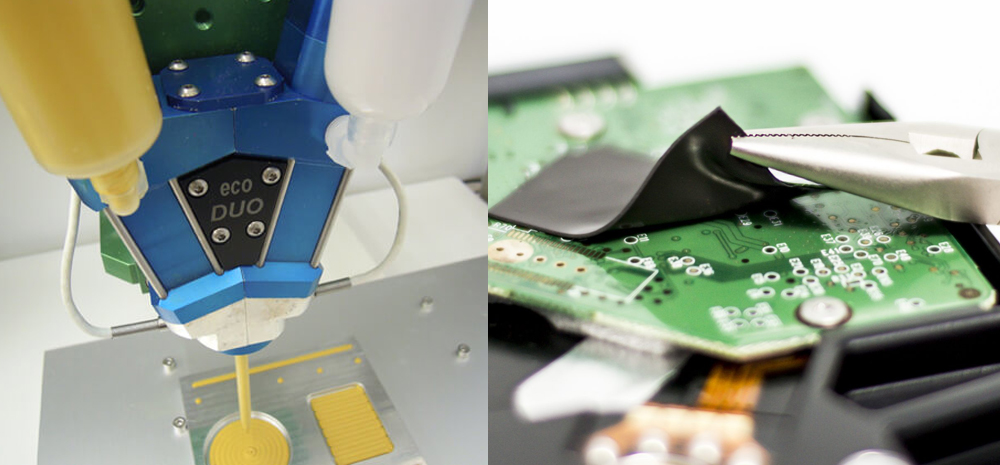

Easy to apply: Thermal grease usually comes in the form of ointment or gel, which is easy to apply to the surface of electronic components. They have a certain viscosity, which can be kept in the desired position after application, are not easy to flow, and are convenient for installation and maintenance.

Improve device performance and stability: By effectively controlling temperature, thermal grease can help electronic devices stay within a suitable operating temperature range, avoiding performance degradation or failure due to overheating. Therefore, it indirectly improves the performance and stability of the device.