+86-13928321129

jiahewell@jhzhb.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English

Silicone gel has a variety of applications in the manufacture and maintenance of electronic devices. Its properties include high heat resistance, insulation, flexibility, and chemical stability, making it an important material in the following types of electronic devices:

1,Electronic seals: Silicone gel is used to make seals for electronic equipment to ensure that the equipment is effectively sealed against dust, moisture and other environmental factors and improves the durability of the equipment.

2,Electronic cooling pads: In high-performance electronic equipment, silicone gel can be used as a cooling pad to help effectively disperse and remove the heat generated by the equipment and maintain a stable operating temperature of the equipment.

3,Electronic Insulation: Silicone gel plays a role in electronic insulation applications and can be used in cable insulation, insulation covers, insulation boards, etc. to prevent current leakage and electrical interference in electronic equipment.

4,Waterproof and dustproof devices: Electronic devices such as mobile phones, tablets, headphones, etc. are often sealed with silicone gel to provide water and dustproof properties and protect the electronic components inside the device.

5,Electronic Seals: Silicone gel seals are used on buttons, touch screens, interfaces and connectors of electronic devices to ensure they function properly in wet and harsh environments.

6,Electronic screen protection: Electronic screens such as mobile devices, tablets, and televisions often use silicone gel screen protectors to increase scratch and impact resistance.

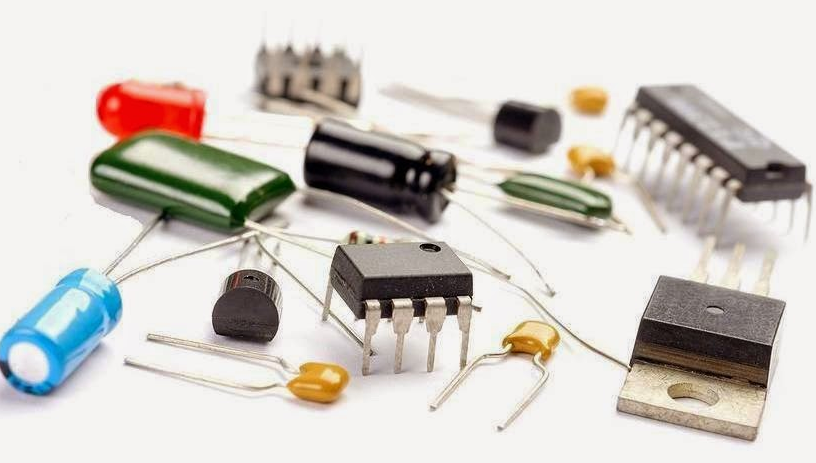

7,Electronic Electronic Component Packaging: Silicone gel is used in the packaging of electronic components to provide protection, insulation and moisture-proof properties, such as transistor packaging and capacitor packaging.

8,Electronic Batteries: Silicone gel is often used for sealing and protection in battery assembly to ensure battery safety and performance.

9,Electronic RF Applications: Silicone gel is used in RF electronic equipment to insulate and seal cables, antennas, and RF modules to reduce electromagnetic interference.

10,Sensors: Some sensors require protection and insulation, and silicone gel can be used to package and seal the sensor element to ensure proper operation.